| أنواع المعدات |

|

|

Chengnan Industrial Park, Rudong, Nantong, Jiangsu, 226400

الصين

|

معلومات عن العاملين

جهات اتصال مفيدة

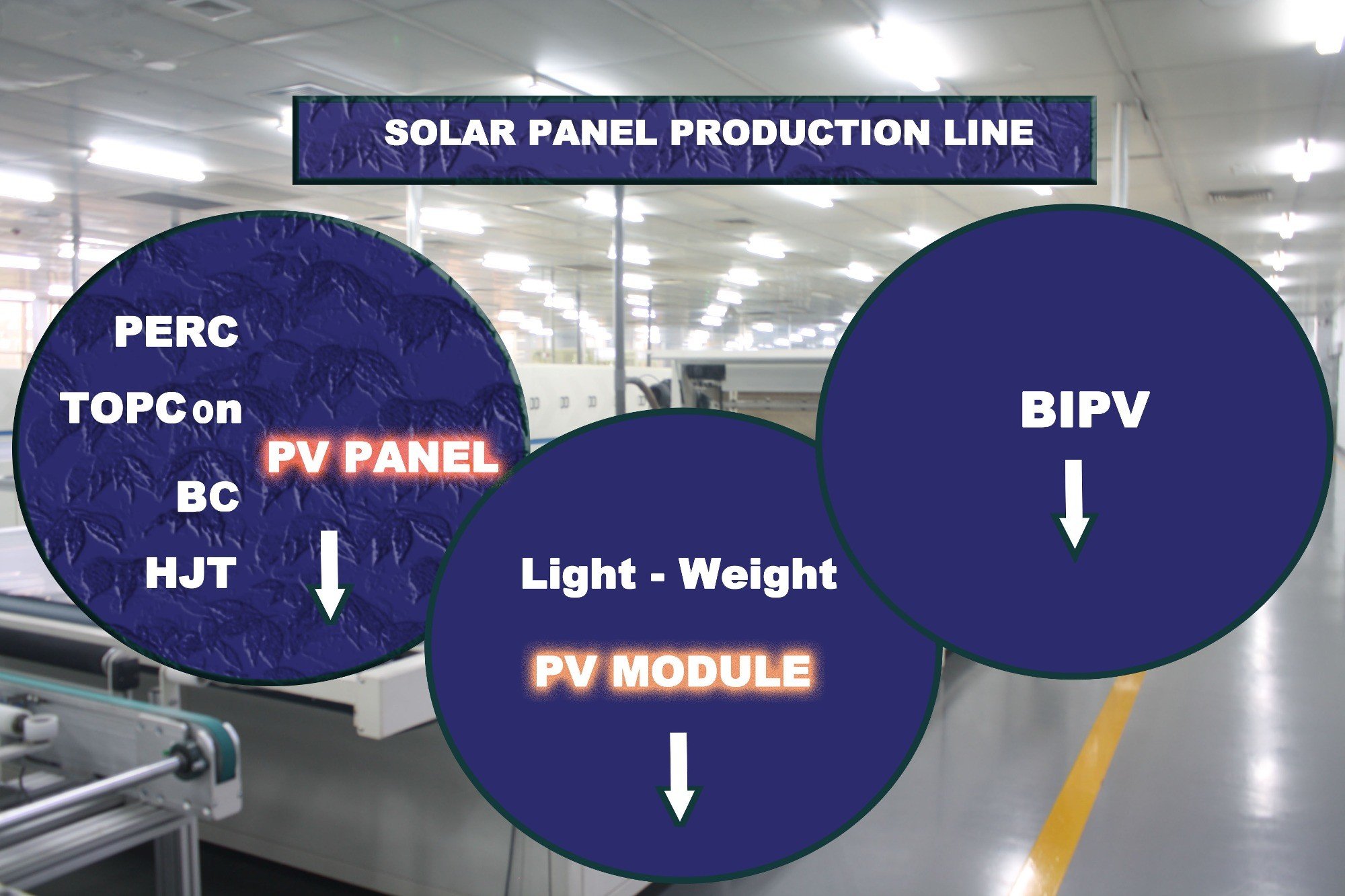

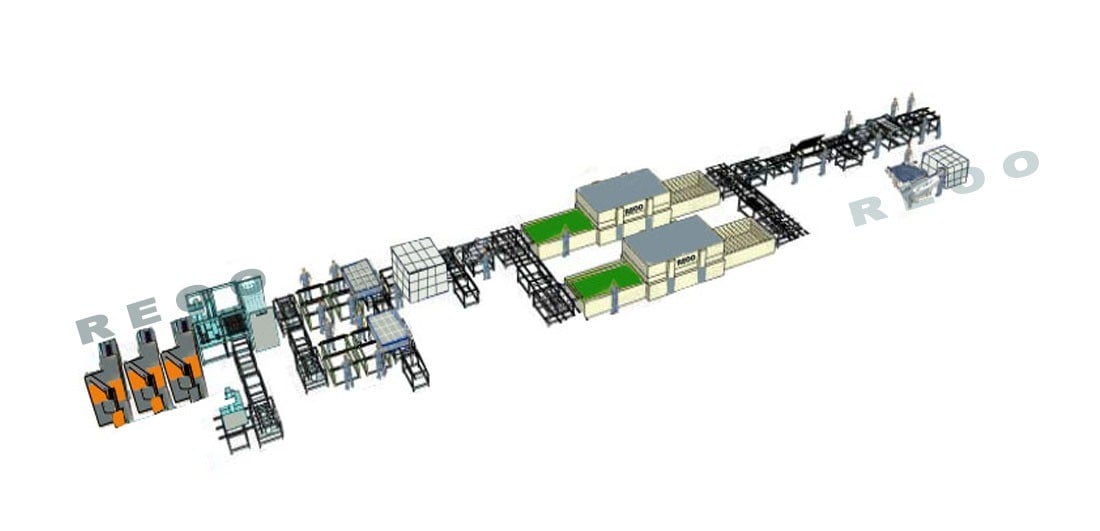

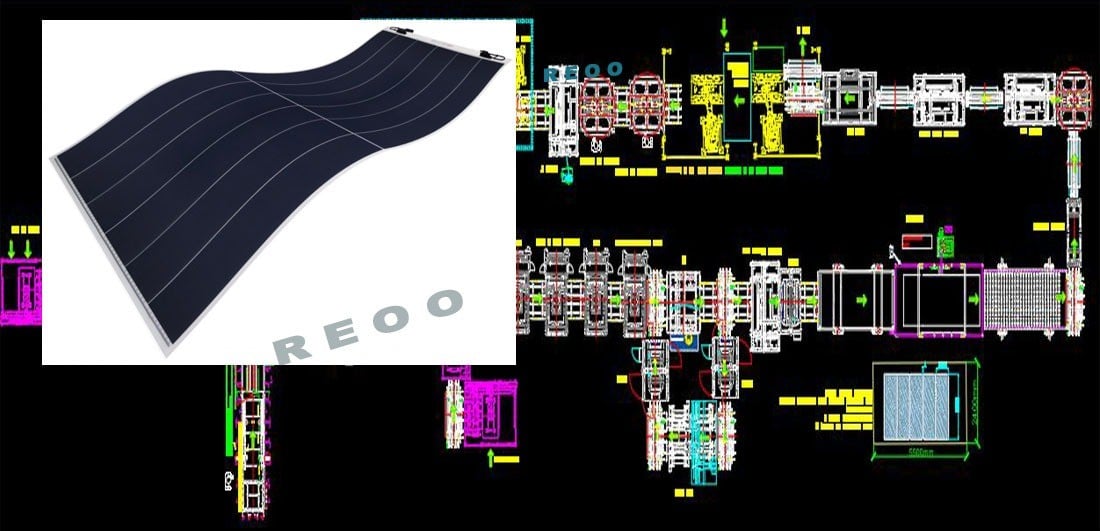

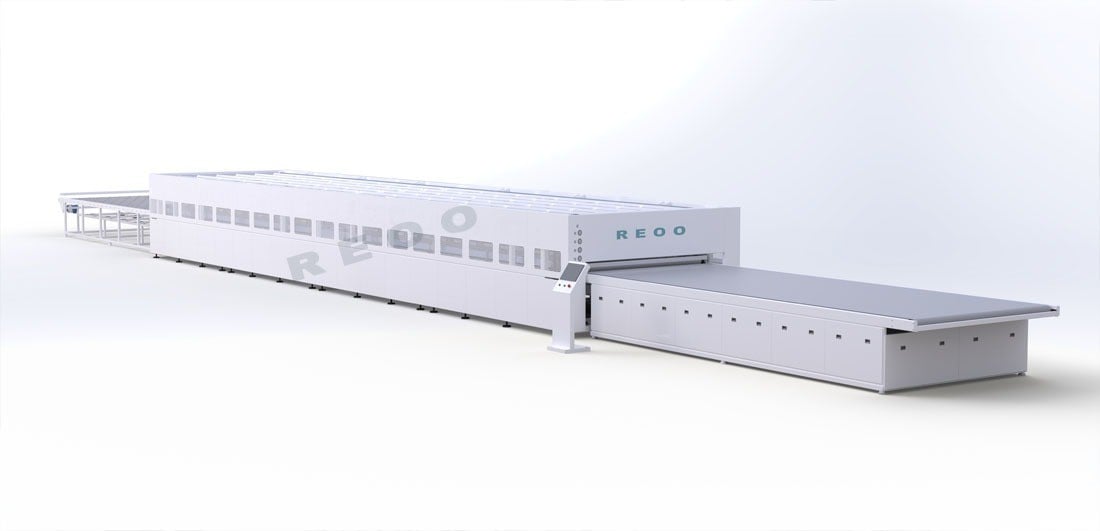

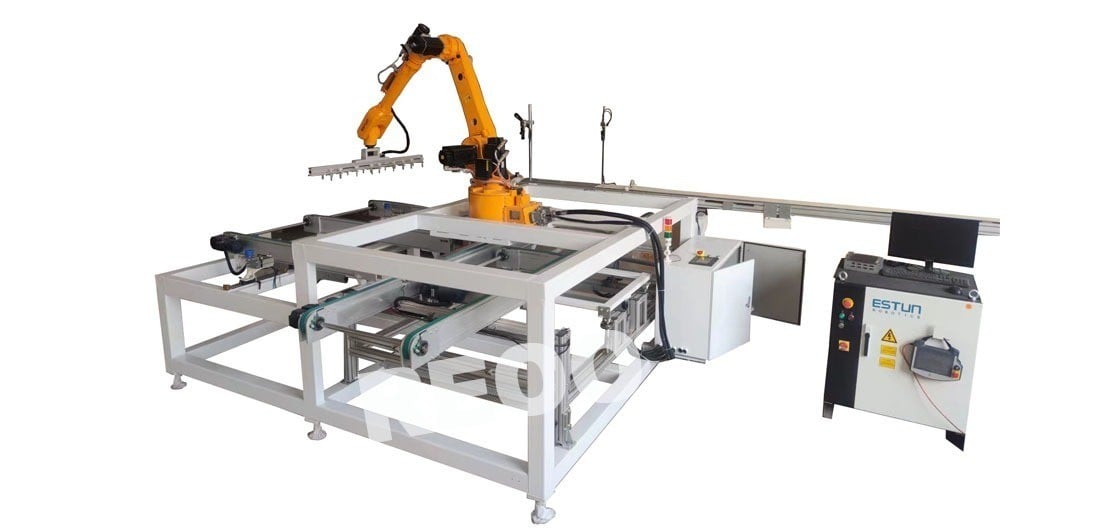

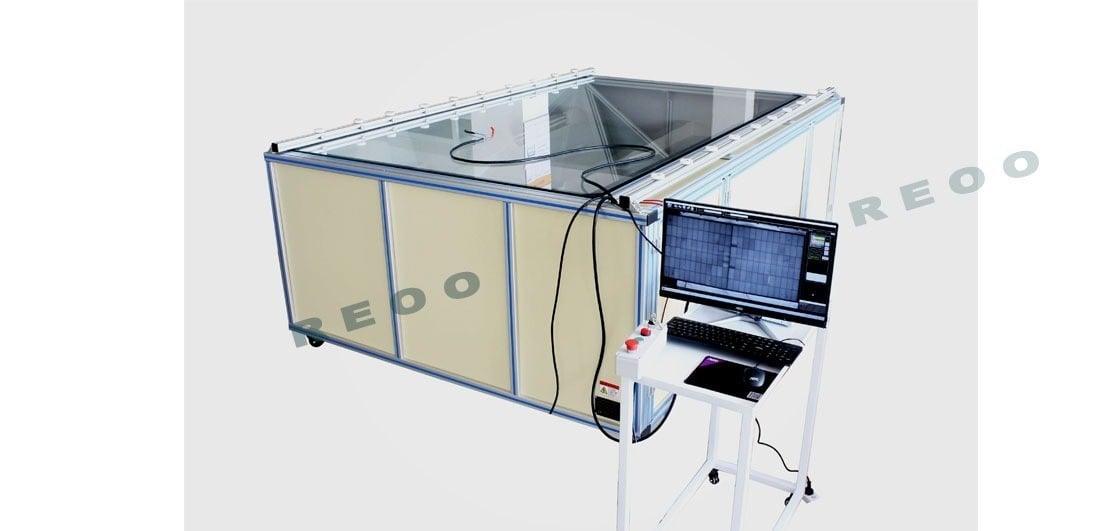

تأسست شركة Reoo Technology Co., Ltd. في عام 2005. وهي مؤسسة تقنية خاصة متخصصة في التصميم والبحث والتطوير وتصنيع مجموعات كاملة من خطوط إنتاج الألواح الشمسية. تشمل منتجات الشركة بشكل أساسي خطوط إنتاج الألواح الشمسية بإنتاج سنوي يتراوح بين 5 ميجاوات إلى 1 جيجاوات، ونحن نقدم حلولًا متكاملة. نحن ننتج بشكل أساسي آلات تغليف الألواح الشمسية، وآلات تقطيع الخلايا، وآلات قطع اللفائف، وآلات لحام السلسلة، وآلات التنضيد، وآلات لحام حزام الحافلة، واختبار EL، واختبار IV، وآلات التأطير، وخطوط التجميع وغيرها من المعدات.

يقع المقر الرئيسي للشركة في مدينة Nantong بمقاطعة Jiangsu، وتستغرق الرحلة من مطار Shanghai Hongqiao إلى شركتنا ساعة ونصف بالسيارة. تمتلك الشركة قاعدتي إنتاج، مصنع تغليف ومصنع للمعدات المساعدة، بالإضافة إلى مركزين للبحث والتطوير ومركز أعمال.

تمتلك الشركة 28000 متر مربع من الأراضي ولديها مصانع ومباني مكتبية موحدة. تمتلك الشركة قسم البحث والتطوير، قسم الإنتاج، قسم التسويق، قسم الإدارة، القسم المالي، قسم خدمة ما بعد البيع، إلخ.

نظرًا لأننا نركز بشكل أساسي على معدات إنتاج الألواح الشمسية ذات الأتمتة العالية، وتكاليف الإنتاج المنخفضة، والوظائف المخصصة، وخدمة ما بعد البيع في الوقت المناسب، فإن معداتنا يتم تصديرها إلى أكثر من 80 دولة حول العالم وتحظى باستقبال جيد من قبل العملاء.

| الولايات المتحدة | Abloomax |

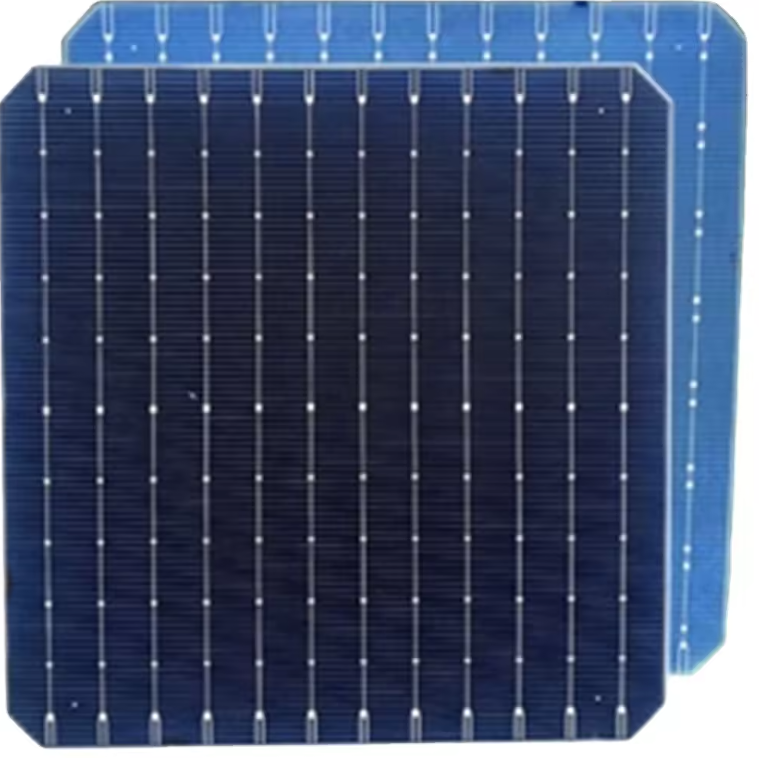

| أنواع المواد | مانع التسرب ،شريط من الرصاص ،زجاج فائق النقاء ،طبقة PET للحماية الخارجية ،EVA ،موصل ،إطار ،خلية ،النحاس ،صندوق توصيل سيليكون |

| نوع السلك | أحادي اللب |

| REOO Company is a reputable provider of production line solutions that is worth to work with and would always recommend their products. Their company has rich experience in customized design, overseas installation, and timely after-sales service. They have customers all over the world and can meet the needs of different customers. All in all, it is a reliable partner. |

| -- Catherine chen, Techwise Solar Technology Co., Ltd. |